ERW Tube Mill, 16mm-63.5mm

Request a Quote

Round, Square, Rectangular Tube

1 ERW76 Sizing section

ERW219 Forming section

ERW254 Sizing section

FF forming technology

Automatic stacking machine

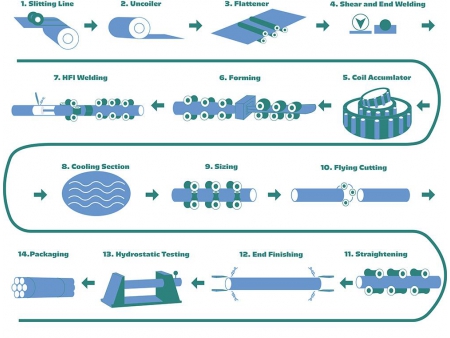

Steel Coil → Double-arm Uncoiler → Shear and End Cutting & Welding → Coil Accumulator → Forming (Flattening Unit Main Driving Unit Forming Unit Guide Unit High Frequency Induction Welding Unit Squeeze Roller) → Deburring → Water Cooling → Sizing & Straightening → Flying Saw Cutting → Pipe Conveyor → Packaging → Warehouse Storage

Basic Technical Parameters| Production Capacity | |

| Round Pipe | 16mm - 63.5mm |

| Square & Rectangular Pipe | 15*15 - 50*50(60*40)mm |

| Wall Thickness | 0.6 - 3.0mm (Round Pipe) 0.6 - 2.5mm(Square Pipe) |

| Speed | Max. 100m/min |

| Pipe Length | 3m – 12m |

| Steel Strip Specification | |

| Material | Low Carbon Steel, Q235, Q195 |

| Coil Inner Diameter | 460 - 510MM |

| Coil Outer Diameter | Max. 1500mm |

| Strip Width | 50mm – 200mm |

| Strip Thickness | 0.6mm – 3.0mm |

| Max. Coil Weight | 2500kgs |

| Electricity | |

| Dynamic Power | 380V, 3-phase, 50Hz (depends on local facilities) |

| Control Power | 220V, single-phase, 50 Hz |

| Electric Installed Capacity: Approx.200kW | |

| Water Cooling | |

| Reservoir for High Frequency Equipment | 15 m³ |

| Reservoir for Circulating Cooling Water | 15 m³ |

| Compressed Air | |

| Pressure | 0.4MPa |

| Flow Rate | 0.5m³/hour |

| Line Speed: Max. 100m/min | |

| Overall Production Line Dimension: 60m X 5m (L X W) | |

Each production line is carefully designed and produced according to customer requirements. We are devoted to providing customers with the best fit line.