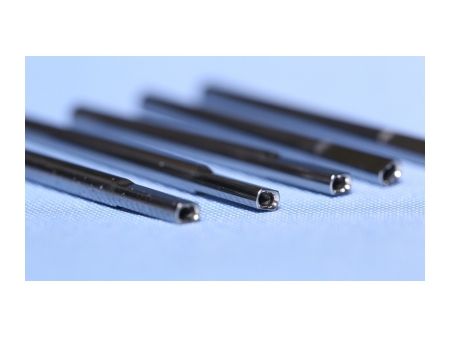

Pure Tungsten Electrodes

The pure tungsten electrodes, with no any addition of oxide, are the earliest electrodes used in TIG welding of magnesium and aluminum. They are mainly used for DC welding instead of AC welding in that this pure tungsten welding electrode may provide bad arc starting, even no arc, and arc instability and easy burn-off as well in AC welding.

Only by means of addition of rare earth oxides can such situation be improved. In addition, the DC welding rod can be used as resistance welding electrode.

Technical Parameters of Pure Tungsten Electrodes

| Model | Oxide Addictive | Impurities Content% | Tungsten Content % | Color standard | |

| Type | Content% | <0.2 | Balance | Green | |

| -- | -- | ||||

Product Standard

ISO 6848, ANSI/AWS, A5.12/A5.12M-98

Specifications

1. Diameter: 0.5-25mm

2. Length: 150mm, 175mm, 178mm (other lengths are available depending on customer's requirements)

Electrode Diameter in Different Current Range

| Electrode Diameter | DC(A) | AC(A) | |||

| In | Mm | DCEN (-) | DCEP ( ) | Imbalanced Wave | Balanced Wave |

| 0.04" | 1.0 | 15-80 | 10-80 | 20-60 | |

| 1/16" | 1.6 | 60-150 | 10-18 | 50-120 | 40-100 |

| 0.079" | 2.0 | 100-200 | 12-20 | 70-160 | 60-130 |

| 3/32" | 2.4 | 150-250 | 15-25 | 80-200 | 80-150 |

| 1/8" | 3.2 | 220-350 | 20-35 | 150-270 | 120-200 |

| 5/32" | 4.0 | 350-500 | 35-50 | 220-350 | 170-260 |

| 3/16" | 4.8 | 420-650 | 45-65 | 240-420 | 220-340 |

| 1/4" | 6.4 | 600-900 | 65-100 | 360-560 | 250-450 |