ERW Pipe Mill

Wanxin’s ERW tube mill produces steel pipes and tubes that include outside diameters ranging from 10mm to 660mm, pipe walls from as thin as 1.0mm to as thick as 22mm, and steel coil weight ranging from 1t to 30t. With one unit of welded tube mill, operators can produce a variety of pipes, including the low pressure fluid pipes, pipe piling, and the structural tubing. Qualified ERW pipe and tube is supposed to be guaranteed by rough machining firstly, then by finish machining. Check the details about rough machining equipment and finishing equipment for ERW pipe and tube processing.

For steel pipe manufacturers, delivering the best value for money is the key to winning over pipe customers. To do so, they need advanced manufacturing processes backed up by top-notch equipment. Wanxin as a specialist ERW pipe mill manufacturer works with many well-known steel pipe makers in the world, helping them design and build welded pipe production lines for high quality pipes in rectangular and round cross sections. In doing so, steel pipe suppliers can meet their customers’ needs in terms of budget and cost-performance ratio.

Presently in China, Wanxin ERW pipe mill is in operation for many steel pipe companies, like Hengshui Jinghua, Chongqing Shengmin, and Rizhao Jinghua, just to name a few. Many international customers have shown their interest in our welded pipe machinery, and are actively negotiating with us for our high-frequency pipe welder, stainless steel pipe welding machine, and high-precision pipe welder.

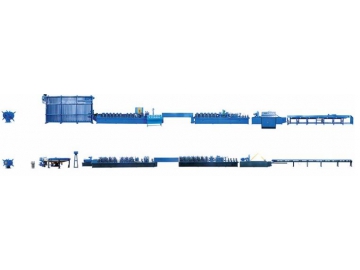

Straight Seam ERW Pipe Production Line

(Loading-Uncoiling-Leveling-Shearing and butt welding-Strip accumulator-Rollforming-High frequency welding-Intermediate annealing-Air cooling-Water cooling-Sizing-Cut to length-End facing and chamfering-Hydraulic testing-UT testing-Marking-Storing)

1.FFX219-630(Forming machine)

2.FFX219-630(Sizing machine)

3.FFX(FFX Mill Roll Configuration)

4.GZHΦ140(GZHΦ140 Cage-roll forming)

5.GZHΦ140(GZHΦ140 Cage-roll forming line)