Stitcher Folder Gluer

Request a Quote

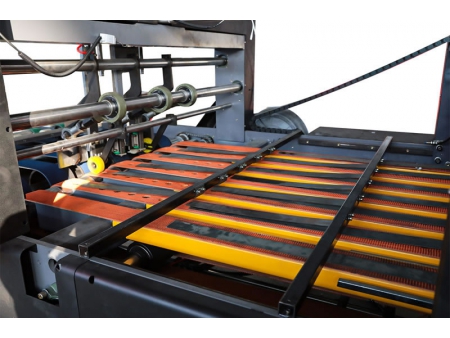

Corrugated Box Automatic Folding Stitching and Gluing Machine

Features

- Statistics regulation, synchronous running of two variable frequency convertor, possessing easy, quick and reliable manipulation mode;

- Computer-controlled and easy and convenient order switch;

- PLC-controlled system and touch screen are designed for convenient operation;

- Automatic paper feeding, glue folding, counting and stacking, average speed at 150 meters/min, high-efficient, energy-saving and labor cost saving;

- Three, five and seven layers of corrugated board are available(seven layers specified)

Paper feeding unit

- Adjustable height of scoring wheel, suitable for 2-8mm cardboard;

- Belt lead edge absorbs air flow to feed paper, accurate and reliable;

- High-end electromagnetic clutch and brake system, individually controlled, easy and reliable operation;

- Front baffle and conveying belt of paper feeding unit are adjustable.

- Lead edge paper feeding via vacuum absorption, ensuring the straightness of carton.

Folder gluer unit

- Imported belt conveyor with strong friction force which can achieve automatic folded transmission;

- Gluing on stainless wheel to well distribute glue quantity, free of failure and saving glue;

- Folder unit is equipped with paperboard and scoring guiding device;

- Two rows of inner adjustable positioning guide rollers are equipped to ensure the right paperboard scoring place;

Counting stacking unit

- Main powering motor speed regulation of variable frequency and stable and reliable booting;

- Belts are designed to transmit cardboard, orderly stacking, speed controlling ranging from 0-130 M/MIN;

- Bottom belt along with upper pressing belt synchronously reinforcing pressure, ensuring enhanced sticking and perfect matching of finished products;

- Stacking height at 8-25 pieces of paper;

- Arbitrarily adjusting nail distance from 30-100mm.

- Single nail, duplex nail and automatically switchable nail are available which can meet various needs of different clients;

- Few minutes are enough to switch carton’s dimension and nail distance which greatly saves time and is convenient for manipulation.

Packing unit

- Individually working, or synchronously working with automatic nail stitching box machine. Step-on or manual control in individual working process, detecting probe is forbidden, extruding line is needed when synchronously working with nail stitching box machine, automatic bundling when getting through detecting probe.

- Duplex laminating to conduct automatic bundling, fuse packing belt width 5-6mm.

Technical specifications

| Stitching unit | Max./mm | 3000x1600mm |

| Min./mm | 800×300mm | |

| Design speed | 200m/min | |

| Stacking height | 400mm | |

| Nailing unit | Max./mm | 3000×1600mm |

| Min./mm | 880×300mm | |

| Design speed | 750nails/min | |

| Nail distance | 30-100mm | |

| Length | 200-900mm | |

| Width | 200-500mm | |

| Min. height | 120mm |

Other Products You May Like