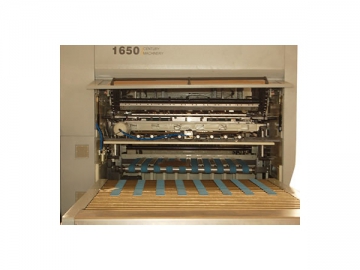

MWZ 1650G Automatic Flatbed Die Cutter

When a high production capacity and a high quality are required, the MWZ1650G automatic flatbed die cutting machine is an ideal choice.

Using advanced gear drive technology, this die cutter can achieve a speed of 5,500 sheets per hour for bulk production.

Based on our research and development team's repeated tests, each spare part is chosen for its high yield and excellent quality.

Features of the MWZ1650G flatbed die cutter include:

Maximum speed: 5,500 sph

ISO9001 and CE approved manufacturing process.

Front waste removal tool

Non-stop delivery system for continuous productivity

Human machine interface

Complete stripping system

Siemens latest PLC technology

Maximum sheet size: 1650*1200mm

Applicable to corrugated board 1-9mm

High speed and precision lead edge feeder

German, Taiwanese and Japanese standard spare parts

Chase loader for quick preparation of next job

Gear drive for stable and fast machine operation

1.Feeding Section

The lead edge feeder allows for consistent and precise feeding of a wide range of corrugated board.

A vacuum suction adjustment is achieved through an inverter for a wide range from F flute to double wall.

2.Feeding Table

Left and right side push lays to ensure accurate alignment and power registration.

Adjustable rubber wheels achieve precise paper feeding.

Double servo systems

3.Die Cutting Section

The centerline system and pneumatic lock-up system is used for a quick cutting die set up and job changeover.

Human machine interface monitors the automatic die cutting machine's working situation and the touch screen control panel makes operation and problem diagnoses easy.

A gear drive system makes machine operation stable and fast.

Heavy duty pneumatic clutch with overload protection for stable and safe machine running.

4. Delivery section

Centerline system for quick stripping die set up.

Double stripping systems and male/female stripping die for different stripping jobs.

Front waste separator to achieve full stripping and front waste transferred to the machine drive side by conveyor belt.

5.Delivery section

Non-stop delivery system for continuous productivity.

Photoelectrical devices are used for safe operation and entrance.

6.Electrical Control

Siemens PLC technology for machine trouble free running.

It also uses electrical components from internationally known brands for a better performance and fast, local after sales service and maintenance.

| Model | |

| Maximum Paper Size | 1650*1200mm |

| Minimum Paper Size | 650*500mm |

| Maximum Cutting Size | 1630*1180mm |

| Maximum Cutting Pressure | 450 T |

| Stock Range | C, B, A Flute and double wall or Corrugated board up to9mm |

| Cutting Precision | ±0.5mm |

| Maximum Speed | 5,500 s/h |

| Height Of Cutting Rules | 23.8mm |

| Pressure Adjusting Range | ±1.5mm |

| Minimum Front Margin | 10mm |

| Inner Chase Size | 1660*1210mm |

| Total Power | 37KW |

| Dimension (L*W*H) | 11200*5560*2550mm |

| Machine ' s Weight | 38 T |