MWZ-S Series Automatic Flatbed Die Cutter

MWZ 1300S & MWZ 1650S

In order to avoid paper scratches for package manufacturers, we have introduced the MWZ 1300S and the MWZ 1650S. Equipped with an advanced feeding system for paper feeding, and a wide stock range for corrugated boards and paper boards, these machines are a great choice for high quality packaging and boxes making.

Processed Materials: Features of this MWZ-S series include:

Human machine interface for easy operation and monitoring machine running situation.

Siemens PLC technology

Complete stripping function

Equipped with world’s leading feeder

Large format of 1650mm and 1300mm

Approved manufacturing process

Centerline system for quick cutting die and stripping die set up

Wide stock range of corrugated board E, C, B, A flute and double wall

1.Feeding Section

The feeding section is equipped with an advanced paper feeding system.

E, B, C, A flue and double walls are applicable with the feeder section.

Flexible paper feeding types for single flute and double wall corrugated board.

There are also four pick up and four forward suction heads with angle adjustment.

2.Feeding Table

The servo system controls the feeding speed.

A photoelectric detector and side guard device is used for high speed feeding and precise registration.

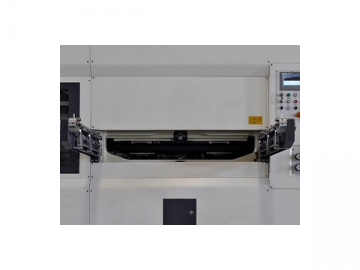

3. Die Cutting Section

A central position system and pneumatic lock-up system is used for a quick cutting die set up and job changeover.

The flatbed die cutter uses internationally known brand names for bearings, the main drive chain and electronic components.

Human machine interface monitors the automatic die cutter’s working situation, as well as provides easy operation and easily understood malfunction diagnoses.

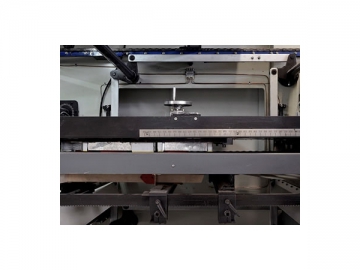

4.Stripping Section

Male/Female stripping plate for different job requirements.

Double stripping function with a lock-up system.

A front waste separator is used to achieve a full stripping and front waste is transferred to the machine’s drive side via conveyor belt.

A centerline system for a fast stripping die set up and job changeover.

5.Delivery Section

Non-stop delivery system for continuous productivity.

A delivery control panel has icons for easy operation.

Photoelectrical devices for safe operation and operator’s machine entrance.

6. Electrical Control System

The electrical control system uses Siemens latest PLC technology.

It also uses electrical components from internationally known brands for better performance and a fast, local, after-sales service and maintenance.

The die cutter is equipped with different safety protection devices. The machine will alarm and stop automatically when problems occur, ensuring the safety of both the machine and operator.

| Model NO. | |

| Maxi sheet size | 1330*980mm |

| Min sheet size | 550*480mm |

| Maxi cutting size | 1300*960mm |

| Maxi cutting pressure | 300 Tons |

| Stock range | E, B, C, A flute and double wall; Paperboard >350gsm |

| Cutting precision | ±0.5mm |

| Pressure adjustment range | ±1.5mm |

| Height of cutting rule | 23.8mm |

| Maxi speed | 4,800 s/h |

| Min front waste | 10mm |

| Inner chase | 1330*980mm |

| Machine power | 27 kw |

| Dimension(L*W*H) | 11140*4600*2566mm |

| Weight | 29 Tons |

| Model NO. | |

| Maxi sheet size | 1650*1200mm |

| Min sheet size | 650*530mm |

| Maxi cutting size | 1630*1180mm |

| Maxi cutting pressure | 400 Tons |

| Stock range | E, B, C, A flute and double wall; Paperboard >350gsm |

| Cutting precision | ±0.5mm |

| Pressure adjustment range | ±1.5mm |

| Height of cutting rule | 23.8mm |

| Maxi speed | 4500 s/h |

| Min front waste | 10mm |

| Inner chase | 1650*1200mm |

| Machine power | 34KW |

| Dimension(L*W*H) | 11946*5549*2644mm |

| Weight | 39 Tons |