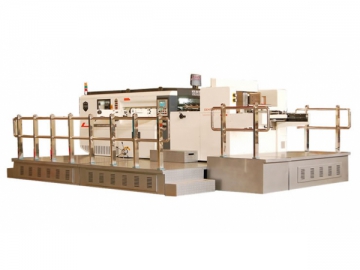

MWZ-B Series Automatic Flatbed Die Cutter

MWZ 1160B/ MWZ 1300B/ MWZ 1450B/MWZ 1620B

The MWZ-B series automatic flatbed die cutting machines were specifically developed for corrugated board converting from 1 to 8.5mm. With high precision lead edge feeder, semi-stripping station, non-stop delivery, and a Photoelectrical devices, the work process is accurate, stable and safe.

Features of the MWZB series flatbed die cutters include:

Centerline system for quick cutting die and stripping die set up and job change

With semi-stripping system to reduce stripping jobs and save labors

Human machine interface for east operation and machine running monitoring

Siemens latest PLC technology

High precision lead edge feeder

Four models for different formats

Wide stock range for corrugated board

Photoelectrical devices for safe operation

European, Taiwanese and Japanese standard spare parts

ISO9001 and CE approved manufacturing process.

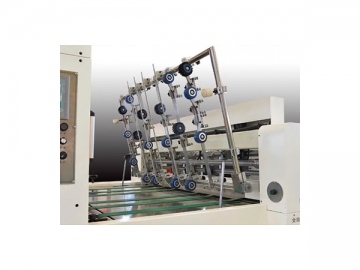

1.Lead Edge Feeder

The high precision lead edge feeder allows for consistent and precise feeding of a wide range of corrugated board.

Vacuum suction adjustment is achieved through an inverter for a wide stock range from E, B, C, A flute to double wall corrugated board.

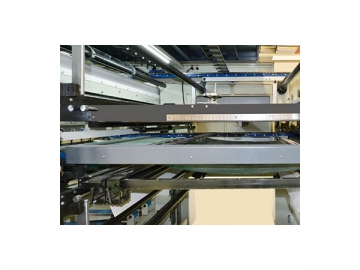

2.Feeding Table

The servo system ensures an accurate alignment and power registration.

3. Die Cutting Section

A centerline system and pneumatic lock up system for quick cutting die set up and job changeover.The bearings and heavy duty pneumatic clutch feature overload protection for a stable and safe machine operation.

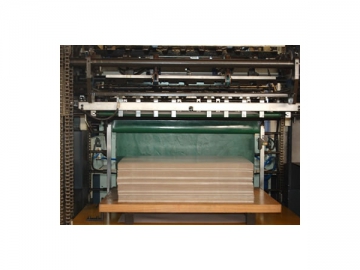

4.Stripping Section

A centerline system is used for a quick striping die set up.

Double stripping and male/female stripping plate for different jobs.

Automatic stripping is carried out on three sides and down the middle.

The automatic lifter is electrically controlled.

5.Delivery Section

Photoelectrical devices ensure a safe operation and entrance.

The delivery control panel has icons that make operation easy.

6. Electrical Section

The electrical section uses components from internationally known brands for a better performance and fast, local after-sales service and maintenance.

There are a number of safety protection devices installed on the die cutting machine, and it will alarm and stop automatically when problems arise. This guarantees the safety of both the operator and the machine.

The use of Siemens latest PLC technology also ensures a safe and trouble free operation.

| Model NO. | |

| Maximum Paper Size | 1180*900mm |

| Minimum Paper Size | 450*400mm |

| Maximum Cutting Size | 1160*880mm |

| Maximum Cutting Pressure | 200 T |

| Stock Range | Corrugated board up to7mm |

| Cutting Precision | ±0.5mm |

| Maximum Speed | 4,200 s/h |

| Pressure Adjusting Range | ±1mm |

| Height Of Cutting Rule | 23.8mm |

| Minimum Front Waste | 8mm |

| Inner Chase Size | 1190*910mm |

| Machine Dimension (L*W*H) | 7275*2385*2195mm |

| Total Power | 22.7 kw |

| Machine's Weight | 17 T |

| Model NO. | |

| Maximum Paper Size | 1330*980mm |

| Minimum Paper Size | 550*480mm |

| Maximum Cutting Size | 1300*960mm |

| Maximum Cutting Pressure | 250 T |

| Stock Range | E, B, C, A flue and double wall, Corrugated board up to8.5mm |

| Cutting Precision | ±0.5mm |

| Maximum Speed | 4,200 s/h |

| Pressure Adjusting Range | ±1mm |

| Height Of Cutting Rule | 23.8mm |

| Minimum Front Waste | 8mm |

| Inner Chase Size | 1330*990mm |

| Machine Dimension (L*W*H) | 7645*4645*2220mm |

| Total Power | 26.2 kw |

| Machine's Weight | 20 T |

| Model NO. | |

| Maximum Paper Size | 1480*1080mm |

| Minimum Paper Size | 480*550mm |

| Maximum Cutting Size | 1450*1050mm |

| Maximum Cutting Pressure | 300 T |

| Stock Range | E, B, C, A flue and double wall, Corrugated board up to8.5mm |

| Cutting Precision | ±0.5mm |

| Maximum Speed | 40,00 s/h |

| Pressure Adjusting Range | ±1mm |

| Height Of Cutting Rule | 23.8mm |

| Minimum Front Waste | 8mm |

| Inner Chase Size | 1480*1080mm |

| Machine Dimension (L*W*H) | 8195*4856*2235mm |

| Total Power | 33.7 kw |

| Machine's Weight | 22 T |

| Model NO. | |

| Maximum Paper Size | 1650*1210mm |

| Minimum Paper Size | 550*650mm |

| Maximum Cutting Size | 1620*1190mm |

| Maximum Cutting Pressure | 300 T |

| Stock Range | E, B, C, A flue and double wall, Corrugated board up to8.5mm |

| Cutting Precision | ±0.5mm |

| Maximum Speed | 40,00 s/h |

| Pressure Adjusting Range | ±1mm |

| Height Of Cutting Rule | 23.8mm |

| Minimum Front Waste | 8mm |

| Inner Chase Size | 1646*1220mm |

| Machine Dimension (L*W*H) | 8895*5241*2295mm |

| Total Power | 37.2 kw |

| Machine's Weight | 27 T |