FBP Closed Circuit Cooling Tower

By using our FBP closed circuit cooling tower, no water incrustation and biological sludge will deposit in the chiller, thus the heat resistance won’t increase and the through-flow area won’t decrease. Besides, the heat exchanger and filter will also be protected from being blocked, keeping the heat exchange efficiency stable. The metal fatigue, caused by the high temperature of the heat exchanger’s surface, can also be avoided. In addition, without water incrustation, the pipe can be prevented from the corrosion by the incrustation, and thus longer service life can be achieved.

Feature of FBP closed circuit cooling tower

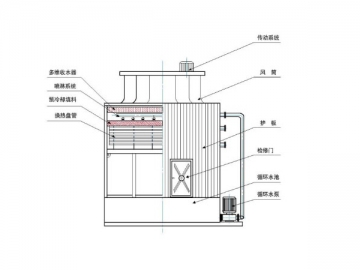

1. The heat dissipation mechanism of the closed circuit cooling tower consists of heat dissipation material and heat exchanging pipe coil. The cooling efficiency is quite high, while the product size is small.

2. Shutter blades are used to cover the air inlet to keep the tower inner wall from direct contact with sunshine. Thus alga growth can be avoided and the water can be kept clean.

3. T12 copper pipe is used for the exchanger of the closed circuit cooling tower, keeping the flow inside clean. Its rated pressure endurance is 1.6MPa.

4. The heat exchanging pipe coil comes in modular design. An access door is available for maintaining the inside components like nozzle, heat dissipation material, ball float valve, and so on.

5. An aluminum alloy axial flow fan is adopted for our closed circuit cooling tower. It can provide high speed air flow, avoid the returning of hot air. Besides, the working noise is quite low.

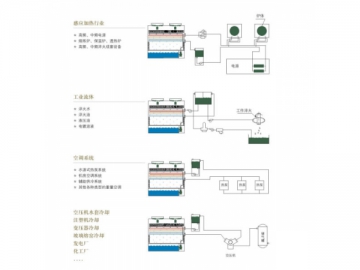

Advantage

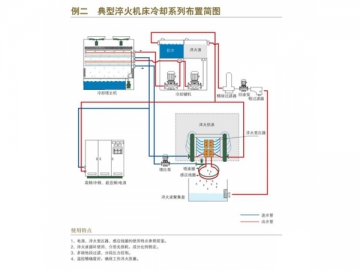

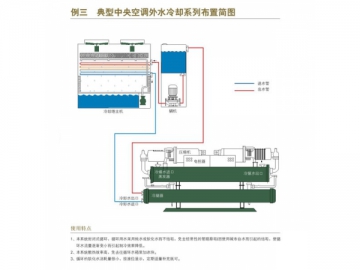

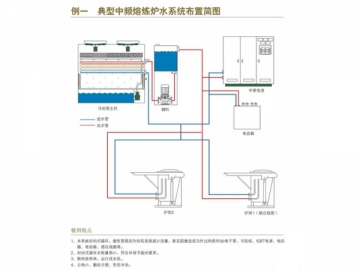

1. The closed circulation system can avoid the disposition of incrustation which can reduce the flow volume and even block the pipe. If the pipe is blocked, some components like electron tube, silicon controlled rectifier, GBT power supplier, electric reactor, capacitor, induction coil, and so on, could be damaged by overheat.

2. Limited water is consumed during the operation, so the closed circuit cooling tower, as one of the air conditioner parts, is quite eco-friendly.

3. The heat dissipation is highly efficient, and the operational cost is quite low.

4. Small installation area is needed. As a HVAC component, its small size can facilitate its moving. Besides, you do not have to dig a water pool before its operation.

2. Features

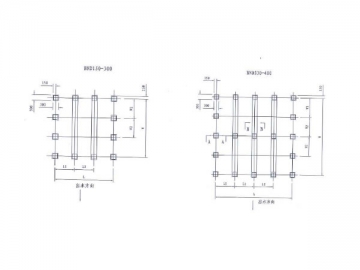

1) Cooling coils

Cooling coils are comprised of several sets of spiral heat exchangers. The design has some shining point compared to other products. Firstly, each set is connected in parallel at the horizontal direction and three sets form a regular triangle. Secondly, every heat exchanger adopts high efficient T2 copper tubes, featuring high thermal conductivity, uniform thickness, anti-corrosion, anti-voltage and good strength. Thirdly, elbow pipes are soldered and brazed by silver, providing excellent leakproofness and connectivity. Fourthly, some spare flanges are left in the water tanks for maintenance and inspection. Fifthly, a reverse-flow structure guarantees the cooling coils a high thermal conductivity. Heating medium and air sections are both designed of low pressure, saving the energy consumption. Sixthly, there are vent valves and drain valves at the top and bottom of the water tank, in consideration of operation and maintenance in winter or transitional seasons. With those wonderful components and parts, our cooling coils do well in the cooling work safely and efficiently.

2) Draught fans

We adopt a special draught fan to match with our cooling tower. This kind of fan has the following features: large wind volume, low noise, small vibration, low energy consumption, anti-corrosion and long lifespan. This match has optimized the function and operation of our cooling tower and maximized its cooling capacity.

3) Cooling filler

When you have a certain requirement for the cooling temperature difference, our pre-cooling filler is ideal for this job. Produced from PVC filler materials (oxygen index≥32) and vacuum molded, our filler features in plasticity, anti-aging, environment-friendly, low temperature resistance (as low as -30℃). The filler is designed a inclined waveform and a bumped surface, extending the heat exchanging time between hot water and cool air. Such design provides a high heat exchanging efficiency and also wins us a reputation of excellent thermal performance, even higher than the national standard. If your factories or plants are in somewhere with extreme cold temperature, our products are available and suitable for you.

4) Water distribution system

In order to evenly spray the water to every corner, water distribution system adopts PVC-U tubes, looped structure and fixed sprayers. All sprayers are produced from ABS materials, free from water rusting and short lifespan.

5) Cover

The cover of our sealed cooling tower is assembled without any welding. The entire cover is comprised of galvanized plates, which are painted with anti-corrosion paint. Its protective panel could be used FRP materials if you have such requirements.

6) Anti-freezing measures

We take different anti-freezing measures for different parts. For cooling coils, we put glycol in the cooling water. (You can refer to our maintenance manual for specific amount) Also, we installed cooling coils at an inclined angle, ensuring the smooth outlet of water. For spraying devices, we install an electric heater in the water collecting tank to avoid cold and freezing.

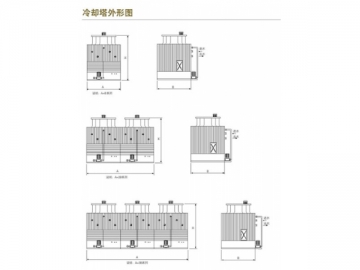

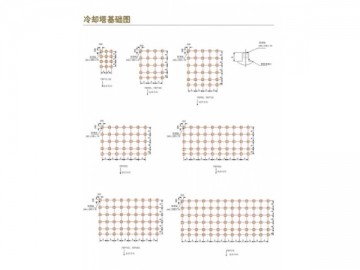

| Parameter of FBP | ||||||||||||

| Model | Motor Power (kW) | Fan Diameter (mm) | Pump Power (kW) | Pressure Drop of Cooling Coils (KPa) | Net Weight (kg) | Operating Weight (kg) | Input Water DN | Output Water DN | Overflow Water DN | Compensated Water DN | Fast-Compensated Water DN | Size (mm) AxBxC |

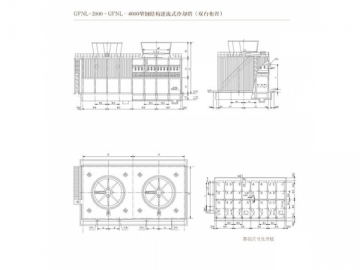

| 15 | 1.1 | 900 | 0.75 | 3.01 | 920 | 1830 | 65 | 65 | 50 | 15 | 15 | 1400*1400*2400 |

| 20 | 1.5 | 1200 | 0.75 | 4.6 | 1220 | 2560 | 65 | 65 | 50 | 15 | 15 | 1600*1600*2400 |

| 30 | 2.2 | 1400 | 1.1 | 7.57 | 1460 | 3066 | 80 | 80 | 50 | 15 | 15 | 2000*2000*3000 |

| 40 | 3 | 1500 | 1.5 | 10.8 | 1620 | 3402 | 100 | 100 | 50 | 15 | 15 | 2400*2400*3200 |

| 50 | 3 | 1800 | 3 | 15.63 | 1780 | 3740 | 100 | 100 | 50 | 15 | 15 | 2600*2600*3900 |

| 65 | 4 | 2200 | 3 | 22.01 | 2120 | 4450 | 80*2 | 80*2 | 50 | 25 | 25 | 3000*3000*3900 |

| 80 | 4 | 2400 | 3 | 29.12 | 2480 | 4960 | 100*2 | 100*2 | 50 | 25 | 25 | 3200*3200*3900 |

| 100 | 5.5 | 2560 | 4 | 37.94 | 2920 | 5840 | 125*2 | 125*2 | 50 | 25 | 25 | 3600*3600*4200 |

| 125 | 7.5 | 3000 | 4 | 53.75 | 3220 | 6440 | 125*2 | 125*2 | 50 | 25 | 25 | 4000*4000*4200 |

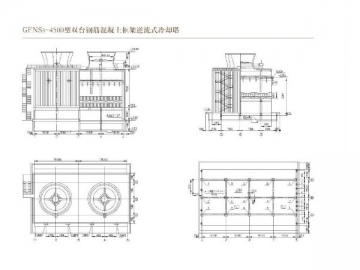

| 150 | 4*2 | 2400*2 | 3*2 | 29.12 | 4710 | 9890 | 100*4 | 100*4 | 50*2 | 25*2 | 25*2 | 6400*3200*3900 |

| 200 | 5.5*2 | 2560*2 | 4*2 | 37.94 | 5540 | 11640 | 125*4 | 125*4 | 50*2 | 25*2 | 25*2 | 7200*3600*4200 |

| 250 | 7.5*2 | 3000*2 | 4*2 | 53.75 | 6120 | 12850 | 125*4 | 125*4 | 50*2 | 25*2 | 25*2 | 8000*4000*4200 |

| 300 | 5.5*3 | 2560*3 | 4*3 | 37.94 | 8270 | 17380 | 125*6 | 125*6 | 50*3 | 25*3 | 25*3 | 10800*3600*4200 |

| 375 | 7.5*3 | 3000*3 | 4*3 | 53.75 | 8620 | 18100 | 125*6 | 125*6 | 50*3 | 25*3 | 25*3 | 12000*4000*4200 |

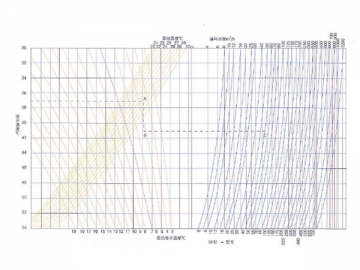

| Conditions of cooling tower: atmosphere pressure P=10130pa; dry bulb temperature=31.5℃ | ||||||||||||