BND FRP Counterflow Cooling Tower

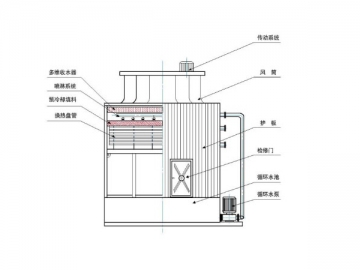

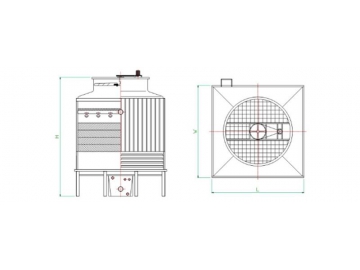

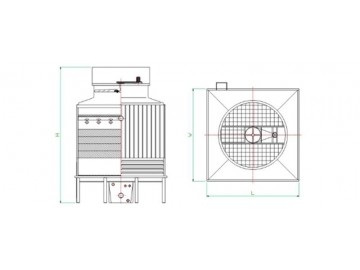

2. Belt and speed reducer

3. Draught fan (aluminium alloy)

4. Air duct (FRP)

5. Maintenance ladder

6. Framework

7. Water collecting device (modified PVC)

8. Water inlet

9. Automatic square sprayer

10.Material filler (modified PVC)

11.Protective panel

12.Blinds

13.Anti-corrosion silencing pad

14.Water collecting tank

15. Water outlet

2. Main Advantages

1) FRP protective panel

a. A silver gray color makes our cooling tower harmony with nearby buildings, showing a beautiful looking.

b. Our tower is covered with high quality uvioresistant gel coat, featuring anti-aging, high strength, anti-acid and anti-alkaline. Those advantages guarantee a long lifespan and little maintenance cost.

c. In a process of rolling pressed and stretching, the FRP protective panel has an elegant structure and looking.

2) Counter-flow cooling tower is equipped with air inlet blinds around the tower, guaranteeing little wind resistance, low noise and a better air flow field.

3) Advantages of cooling materials Our cooling materials adopt excellent quality PVC and are shaped by the vacuum molds. What's more, cooling materials are designed a inclined waveform and a bumped surface, extending the heat exchanging time between hot water and cool air.

4) Water collecting device also adopts PVC and shaped by the vacuum molds. Such designs achieve such advantages as a good plasticity, anti-aging and flame retardant. A comprehensive shape design greatly avoids the drift water loss and wind resistance.

5) The silencing pads are produced from polymer materials, featuring anti-corrosion, good silencing capacity and a dramatic decrease in noise caused by water level difference.

6) The square sprayer enables an entire square spraying area without neither dead angles nor overlapping area. It continuously and evenly sprays the cooling water to every corner. Besides, it also can automatically remove incrustation, guaranteeing a long lifespan and high efficiency.

7) Characteristics of speed reducer

a. Our belt transmission can provide you with a stable performance and vastly lower the noise of mechanical resonance.

b. We adopt imported V-shape belt, gaining an efficient transmission.

c. Our speed reducer is made by professional mechanical plant, offering you guarantees of a long lifespan and little malfunction.

8) Features of motor

We equip our cooling tower with a special motor in order for a long service life.

9) Features of draught fans

Our draught fans are produced from aluminum alloy and undergo a special electrochemical process on its surface. Those special materials and treatment incredibly enhance the operating efficiency, improve its resistant capacity of air corrosion and extend its service life, making our products stand out from other similar products.

10) Wind duct

Low wind resistance and good air flow environment play a vital role in a good wind duct. Our technicians finally find that an arc shape and a smooth surface are the best design for maximizing its efficiency and capacity.

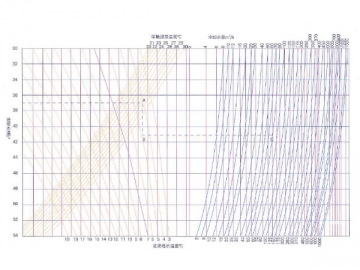

| Parameter of BND | ||||||||||||||

| Model | Water Volume (m3/h) | Cooling Capacity *1000kcal/H | Motor Power (kW) | Diameter of Draught Fan (mm) | Pressure Head (mH2O) | Adding Water Volume (m3/H) | Size | Weight (kg) | Sound Level | |||||

| L | W | H | Net Weight | Operating Weight | P | R | T | |||||||

| BND-90 | 90 | 450 | 2.2 | 1468 | 4 | 1 | 2160 | 2160 | 3500 | 916 | 1856 | 58 | 63 | 50 |

| BND-100 | 100 | 500 | 3 | 1768 | 4 | 1.1 | 2580 | 2580 | 3500 | 980 | 2030 | 59 | 64 | 50.5 |

| BND-125 | 125 | 625 | 4 | 1768 | 4 | 1.4 | 2580 | 2580 | 3500 | 1155 | 2225 | 60.5 | 65 | 51 |

| BND-150 | 150 | 750 | 5.5 | 2360 | 4 | 1.7 | 3120 | 3120 | 3500 | 1346 | 2736 | 60.5 | 65.5 | 52 |

| BND-175 | 175 | 875 | 5.5 | 2360 | 4 | 1.9 | 3120 | 3120 | 3500 | 1410 | 3490 | 62.5 | 66 | 53 |

| BND-200 | 200 | 1000 | 5.5 | 2560 | 4 | 2.2 | 3120 | 3120 | 3500 | 1640 | 3734 | 63 | 67 | 54 |

| BND-225 | 225 | 1125 | 7.5 | 2560 | 4 | 2.5 | 3420 | 3420 | 3500 | 1854 | 3964 | 63 | 67.5 | 54 |

| BND-250 | 250 | 1250 | 7.5 | 2954 | 4.4 | 2.8 | 3900 | 3900 | 4020 | 2028 | 4128 | 63 | 68 | 55 |

| BND-300 | 300 | 1500 | 11 | 2954 | 4.4 | 3.3 | 3900 | 3900 | 4020 | 2456 | 5620 | 63.5 | 68 | 55 |

| BND-330 | 330 | 1650 | 11 | 3340 | 4.4 | 3.6 | 4260 | 4260 | 4020 | 2640 | 5870 | 64 | 68.5 | 55 |

| BND-370 | 370 | 1850 | 11 | 3340 | 4.4 | 4.1 | 4260 | 4260 | 4020 | 2990 | 6140 | 64.5 | 68.5 | 55.5 |

| BND-400 | 400 | 2000 | 11 | 3340 | 4.4 | 4.4 | 4650 | 4650 | 4020 | 3145 | 7092 | 65 | 70 | 55 |

| BND-450 | 450 | 2250 | 15 | 3744 | 4.4 | 5 | 5100 | 5100 | 4220 | 3410 | 7474 | 65 | 71 | 56.5 |

| BND-500 | 500 | 2500 | 18.5 | 3744 | 4.4 | 5.5 | 5100 | 5100 | 4220 | 3685 | 7762 | 65.5 | 72 | 57 |

| BND-600 | 600 | 3000 | 18.5 | 4140 | 4.6 | 6.6 | 5820 | 5820 | 4420 | 4364 | 9004 | 65.5 | 73 | 57 |

| BND-700 | 700 | 3500 | 22 | 4140 | 4.6 | 7.7 | 5820 | 5820 | 4420 | 5380 | 10640 | 66 | 73.5 | 58 |

| BND-800 | 800 | 4000 | 30 | 4140 | 4.8 | 8.8 | 6360 | 6360 | 4720 | 5850 | 11350 | 66 | 74 | 58.5 |

| BND-900 | 900 | 4500 | 30 | 4830 | 4.8 | 9.9 | 7620 | 7620 | 4720 | 6470 | 13650 | 67 | 75 | 59 |

| BND-1000 | 1000 | 5000 | 30 | 4830 | 4.8 | 11 | 7620 | 7620 | 4720 | 6935 | 14432 | 67.5 | 75 | 60 |

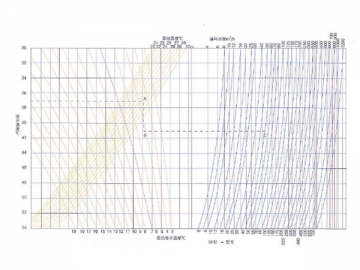

| Notes: 1. The cooling capacity is tested at an input water temperature of 37 ℃ and an output water temperature of 32℃. The wet bulb temperature is 28℃ at atmosphere pressure of 99.4kPa. 2. When the installing position is affected by external factors, we can design a cooling tower of special size for you. 3. If you have special requirements, assembling draught fan units are also available for you. Because of the change in air inlet area, there will be an increase in the height of wind, the height of wind windows and pressure head. You are welcome to contact with us about the specific information. | ||||||||||||||