BHD FRP Crossflow Cooling Tower

As a professional air conditioner supplier in China, GRAD can provide various AC components. Our BHD series FRP crossflow cooling tower is greatly updated on the basis of traditional FRP cooling tower in terms of structure, technique and components. All the components and materials have been strictly selected and tested, ensuring that they have long service life and stable working performance.

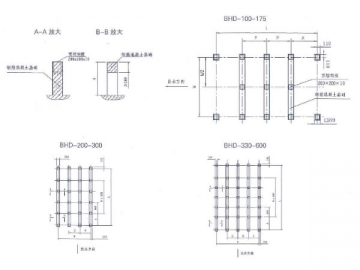

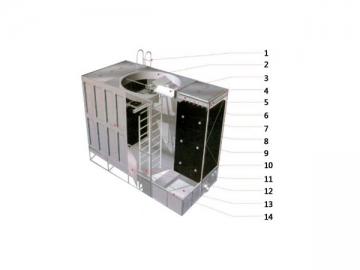

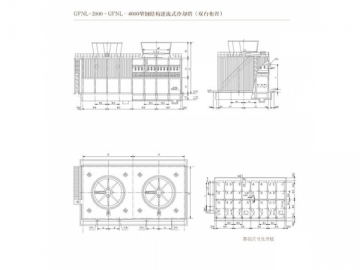

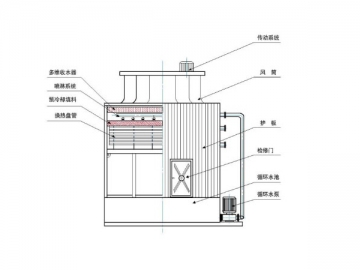

1. Diagram of FRP Crossflow Cooling Tower of BHD Series2.air duct

3.draught fan

4.water tray

5.water inlet

6.sprayer

7.belt and speed reducer

8.energy-saving and low-noise motor

9.protection plate

10.inspection door

11.feed port

12.inspection access

13.water tank

14.tower framework

2. Features

1) Environment friendly

A semi-sealed water tank protects the water from being contaminated by dust, algae and bacteria. It also has an effective system to maintain the cooling water quality. Such special design makes our products stand out from the other similar products.

2) High efficiency

The fixed high efficient square sprayer has sprayed water evenly onto the materials, enlarging the contact area of hot water and cool air. Another feature is that there is no spraying dead angle or overlapping sprayed area, guaranteeing the sustainable use of water and avoiding any waste. Coupled with high efficient draught fans as well as special material fillers, our sprayer has an incredible cooling capacity.

3) Low noise

Our designers have done everything they can to decrease the noise. Our product embodies this advantage from every aspect. Firstly, the material filler is spread on water, greatly cutting the noise caused by water level difference. Secondly, the ceiling-mounted filler units are neatly arranged and equipped with no blinds, enlarging the air inlet area, slowing down the inlet air speed and decreasing the noise. Thirdly, we adopt transmission belts and draught fans with large diameter and low rotate running speed, cutting transmission noise and vibration. Fourthly, draught fans and motors are installed on the top of cooling tower to decrease the noise. What's more, the buffering of GRP air duct also cuts the noise and vibration of draught fans and motors. Compared to other products, these advantages have made cooling tower stand out in the industry.

4) Energy saving

Our products are equipped with big draught fans, allowing for large wind volume and low energy consumption. When it comes to collecting water, we adopt an automatic PVC water collecting device and have a good control of the wind speed, effectively cutting the drift water loss.

5) Stable performance

We have a careful and comprehensive selection of the internal components and parts, in order to optimize the internal structure and maximize the function. With hop dip galvanized steel as raw materials, we adopt a standardized processing method, providing guarantees for dependable and excellent quality.

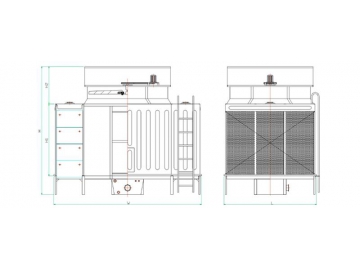

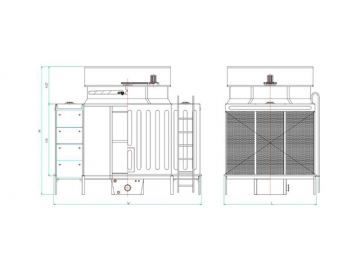

6) Convenient use and light weight

a. The modular structure design features light weight, small volume and high practicability, suitable for multiple models assembled into one unit. If you want a cooling tower with small space occupation and light weight, our products are the most ideal cooling machine for you.

b. The high quality transmission device contributes to a low failure rate of our cooling tower. Our maintenance ladder is on the top of tower, making it pretty convenient for maintenance. One notable feature is that there is no need to shut down the cooling tower during your maintenance. Besides, the security doors connect every internal part of our tower, increasing the maintenance efficiency and simplifying the daily maintenance.

c. We have continuous improvement in our mechanical processing, upgrading our product quality. Meanwhile, our products are also equipped with lighter weight, smaller volume and so on.

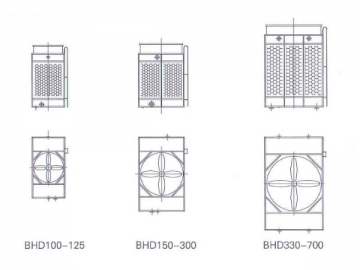

| Model | Water Flow Rate (m3/h) | Cooling Capacity*1000kcal/H | Motor Power (kW) | Diameter of Draught Fan (mm) | Pressure Head (mH2O) | Adding Water Volume (m3/H) | Size | Weight (kg) | Sound Level | |||||

| L | W | H | Net Weight | Operating Weight | P | R | T | |||||||

| BHD-100 | 100 | 500 | 3 | 1768 | 3.5 | 1.1 | 3800 | 2060 | 3350 | 1155 | 2355 | 60.1 | 57.4 | 50 |

| BHD-125 | 125 | 625 | 3 | 1768 | 3.5 | 1.37 | 4200 | 2060 | 3350 | 1254 | 2787 | 61.2 | 57.6 | 51.2 |

| BHD-150 | 150 | 750 | 3 | 2168 | 3.6 | 1.65 | 4200 | 2460 | 3350 | 1452 | 3152 | 61.4 | 57.8 | 51.5 |

| BHD-175 | 175 | 875 | 4 | 2168 | 3.6 | 1.93 | 4600 | 2460 | 3350 | 1672 | 3602 | 62.3 | 58.1 | 52.9 |

| BHD-200 | 200 | 1000 | 4 | 2560 | 3.8 | 2.2 | 4600 | 2860 | 3350 | 1859 | 4129 | 62.5 | 58.7 | 53.4 |

| BHD-225 | 225 | 1125 | 5.5 | 2560 | 3.9 | 2.48 | 5000 | 2860 | 3350 | 2277 | 4677 | 63.1 | 59.3 | 53.8 |

| BHD-250 | 250 | 1250 | 5.5 | 2954 | 4 | 2.75 | 5000 | 3260 | 4000 | 2530 | 5570 | 63.4 | 59.8 | 54.5 |

| BHD-300 | 300 | 1500 | 7.5 | 2954 | 4 | 3.3 | 5400 | 3260 | 4000 | 2838 | 5938 | 64.3 | 60.6 | 55.2 |

| BHD-330 | 330 | 1650 | 7.5 | 3340 | 4.2 | 3.63 | 5400 | 3660 | 4000 | 3179 | 6669 | 63.9 | 60.4 | 54.7 |

| BHD-370 | 370 | 1850 | 11 | 3340 | 4.4 | 4.07 | 5800 | 3660 | 4500 | 3707 | 7712 | 64.2 | 60.7 | 55.4 |

| BHD-400 | 400 | 2000 | 11 | 3744 | 4.4 | 4.4 | 5800 | 4060 | 4500 | 4202 | 8482 | 64.7 | 61.3 | 55.7 |

| BHD-450 | 450 | 2250 | 15 | 3744 | 4.9 | 4.95 | 6200 | 4060 | 4500 | 4433 | 9333 | 65.3 | 61.4 | 56.1 |

| BHD-500 | 500 | 2500 | 15 | 4140 | 5 | 5.5 | 6600 | 4460 | 5000 | 4895 | 10085 | 65.4 | 61.7 | 56.3 |

| BHD-600 | 600 | 3000 | 18.5 | 4140 | 5.3 | 6.6 | 7000 | 4460 | 5000 | 5467 | 10817 | 66.1 | 62.4 | 57.1 |

| BHD-700 | 700 | 3500 | 18.5 | 4540 | 5.3 | 7.7 | 7400 | 4860 | 5000 | 5841 | 12471 | 67.3 | 63.6 | 58.2 |

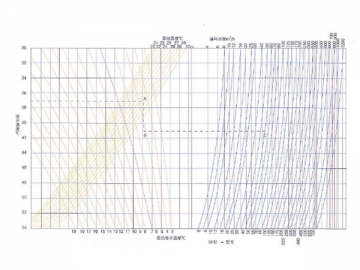

| Notes: 1. The cooling capacity is tested at an input water temperature of 32 ℃ and an output water temperature of 28℃. The wet bulb temperature is 28℃ at atmosphere pressure of 99.4kPa . 2. The sound level is tested at a running frequency of 50 Hz. Please refer to the frequency comparison table for the actual sound level. (This information is subject to change without notice.) | ||||||||||||||

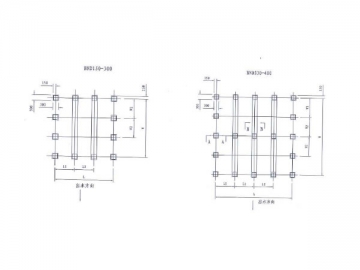

1) This chart shows the net height, without any structure height.

2) At the top of pier are more than 200 mm thick planks. At the bottom, the size of embedded steel is 220*220mm.