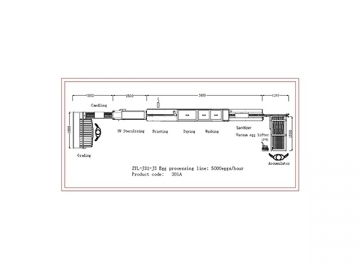

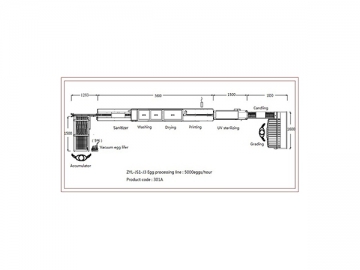

301A Egg Processing Line with Cleaning & Grading (5000 EGGS/HOUR)

ZENYER 301A egg processing line includes the , , , and . This model has a maximum capacity of 5000 eggs/hour, and is used to carry out egg loading & accumulator, automatic sanitizer spraying, washing, drying, UV sterilizing, candling and grading. Users can also choose to have it equipped with as well.

The full processing equipment line can be placed in a straight line, or at left and right angular installations.

- 301A+605G-right

- 301A+605G-Left

- 301A+605G-left turn

- 301A+605G-right turn

| Product name | Egg Processing Line |

| Product code | 301A |

| Model | ZYL-JS1-J3 |

| Capacity | 5000 eggs/hour |

| Material | Stainless steel |

| Power | 13.5 KW |

| Voltage | 220V,50HZ, single phase 380V,50HZ, three phase |

| Dimension(L×W×H) | 10 ×1.7×1.3 M |

| Net weight | 900KG |

| Gross weight | 1100KG |

| Function | Accumulator, vacuum lifter loading, sanitizer spraying, washing, drying, printing, UV sterilizing, candling and grading |

- Vacuum egg lifter & Accumulator

- Sanitizer

- Washing

- Drying

- Single-head printing(option)

- UV sterilizing

- Candling

- Grading (mechanical weighing)

Workers place the eggs on the single feeding line of egg washer by hand.

Or the whole tray can be vacuum lifted onto if using the ZENYER , this would allow 90 eggs(3 trays) loading a time with cost of 30 seconds and keeps the machine running for one minute. The loading worker would have another 30 seconds for some extra work.

Sanitizer equipment sprays disinfectant or detergent on the eggs.

Eggs are fully cleaned using brushes and a warm water spray. The brush modules are flexible, and adjustments can be made to the brush distance, position, and speed.

Eggs are perfectly dried by drying brush and strong air generated by drying fans.

ZENYER can be attached to the end of the egg washer, allowing users to print the farm name, logo, date, best before date, and other information.

UV sterilization equipment eliminates any bacteria on the egg surface.

Eggs will run through LED lights on a belt conveyor to the egg grader for a candeling application, allowing users to pick out any unqualified eggs, such as those with leaks or cracks.

Eggs are mechanically weighed using a leverage principle to ensure a precision sorting, at a maximum of 5 grades and a precision within ±1g.