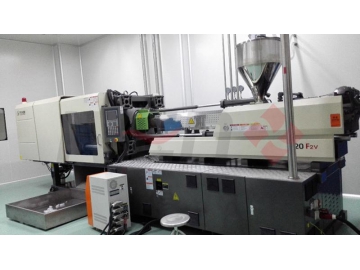

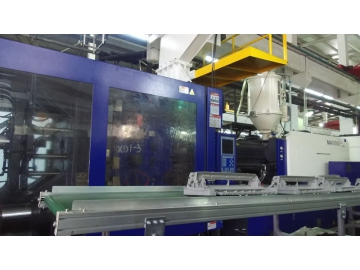

Introduction

The servo motor injection molding blowing machine features an accumulator which utilizes compressed natural gas to store energy. The rapid response battery increases the injection speed and overall efficiency of the equipment. During injection, it releases the pressurized oil and provides instantaneous hydraulic action.

Application

The Timey servo motor injection molding blowing machine is developed for the production of plastic packaging products for electronics, appliances, daily necessities, medical supplies, cosmetics, and other consumer goods.

Parameter

TM-110S8 Servo Motor Injection Molding Blowing Machine | Injection | Model | Theoretical injection volume (cm³) | Shot volume

(g, Oz) | Screw diameter (mm) | Injection pressure (Mpa) | Screw L:D ratio | Screw stoke(mm) | Screw rotate speed (r/min) |

| A | 163 | 148 | 5.2 | 35 | 228 | 21.7:1 | 170 | 0-180 |

| B | 192 | 175 | 6.2 | 38 | 193 | 20:01 |

| C | 235 | 213 | 7.5 | 42 | 158 |

18:01 |

| CLAMPING UNIT | Clamping force (kN) | Opening stroke (mm) | Platen size (mm*mm) | Space between tie bars (mm*mm) | Mold thickness (mm) | Platen Mix stroke (mm) | Ejection stroke (mm) | Injection force (kN) |

| 1100 | 350 | 600*550 | 405*370 | 150*380 | 730 | 100 | 42 |

| Power/Electric Heating | Hydraulic system pressure (Mpa) | Pump motor (kw) | Heating power (kw) | Number of temp. control |

| 17.5 | 12 | 7.5 | 4+nozzle |

| Other | Cycle time (sec) | Tank volume (L) | Machine dimensions (m*m*m) | Weight of machine (kg) |

| 1.3 | 200 | 4.3*1.2*1.8 | 3600 |

TM-400S8 Servo Motor Injection Molding Blowing Machine

| Injection | Model | Theoretical injection volume (cm³) | Shot volume (g, Oz) | Screw diameter (mm) | Injection pressure (Mpa) | Screw L:D ratio | Screw stoke (mm) | Screw rotate speed (r/min) |

| A | 1385 | 1260 | 44.1 | 70 | 206 | 24:01:00 | 360 | 0-135 |

| B | 1810 | 1646 | 57.5 | 80 | 158 | 21:01 |

| C | 2290 | 2084 | 73.8 | 90 | 125 | 19:01:00 |

| CLAMPING UNIT | Clamping force (kN) | Opening stroke (mm) | Platen size (mm*mm) | Space between tie bars (mm*mm) | Mold thickness (mm) | Platen Mix stroke (mm) | Ejection stroke (mm) | Injection force (kN) |

| 4000 | 710 | 1060*1040 | 730*710 | 250-730 | 1400 | 185 | 111 |

| Power/Electric Heating | Hydraulic system pressure (Mpa) | Pump motor (kw) | Heating power (kw) | Number of temp. control |

| 17.5 | 37 | 35.85 | 5+nozzle |

| Other | Cycle time (sec) | Tank volume (L) | Machine dimensions (m*m*m) | Weight of machine (kg) |

| 5.1 | 820 | 8.6*1.75*2.35 | 17000 |

TM-800S8 Servo Motor Injection Molding Blowing Machine

| Injection | Model | Theoretical injection volume (cm³) | Shot volume (g, Oz) | Screw diameter (mm) | Injection pressure (Mpa) | Screw L:D ratio | Screw stoke (mm) | Screw rotate speed (r/min) |

| A | 2558 | 2327 | 81 | 85 | 218 | 24.5:1 | 450 | 0-130 |

| B | 3195 | 2907 | 101 | 95 | 175 | 22:01 |

| C | 3903 | 3552 | 124 | 105 | 143 | 20:01 |

| CLAMPING UNIT | Clamping force (kN) | Opening stroke (mm) | Platen size (mm*mm) | Space between tie bars (mm*mm) | Mold thickness (mm) | Platen Mix stroke (mm) | Ejection stroke (mm) | Injection force (kN) |

| 8000 | 1000 | 1450*1385 | 1030*940 | 400-1000 | 2000 | 300 | 200 |

| Power/Electric Heating | Hydraulic system pressure (Mpa) | Pump motor (kw) | Heating power (kw) | Number of temp. control |

| 17.5 | 31+39 | 49 | 6+nozzle |

| Other | Cycle time (sec) | Tank volume (L) | Machine dimensions (m*m*m) | Weight of machine (kg) |

| 7 | 1500 | 10.6*2.6*2.7 | 42000 |

Accessories brand

Servo pump: Rexroth (High) Eckerle(Normal)

Servo system: Rexroth (High) Techmation(Normal)

Hydraulic motor: Intermot

Reversing valve: Vickers

Control system: Mirle 9118/Techmation Q8

Electronic components: Schneider

Electronic ruler: Novo

Features

1. High energy savings: the injection molding machine is outfitted with a Hongxun servo system. Optimally, the pump system is 40% more energy efficient than variable pump systems and 70% more efficient compared to quantitative pump systems.

2. High precision: the low pressure domain and low flow field is ±0.5%. with high repeatability. The error rate of plastic products after molding is within a range of 0.4% to 0.7%. This is near the level of semi-closed loop control.

3. Fast response: the stable servo motor is equipped due to its high precision and sensitivity pressure feedback device. This forms a precision closed-loop control and effectively shortens the time of production and improves overall efficiency.

4. Low noise: the hydraulic control structure is specially designed to minimize noise output and run with optimal smoothness.

5. Low temperature rise: the motor turns on only during use. When the motor is turned off, excess heat will not build up. This reduces the heat in the oil system and removes the need to cool the oil. High temperature oil can damage hydraulic components.

6. Easy operation: the injection machine controls the artificial circuit of the input pressure and flow. When the pressure approaches the set pressure level, the system automatically changes to pressure control so the operator does not need to perform complicated actions to get the machine working properly.

7. Low oil consumption: lower oil temperatures conserve hydraulic components. The oil cleaning system quickly and effectively filters grease to ensure that oil is clean and free from debris.

8. Servo energy saving system: the servo motor oil and electric composite structure feature high precision operation with an incredible response time. It also provides the equipment with low noise and good power saving performance. The servo motor injection molding blowing machine can reach the maximum output value of 0.05s. Compared to traditional machines, the response speed is notably superior and the cycle is shortened effectively.

We offer plastic machines for making plastic packaging bottles and containers. Our servo motor injection blow molding machine is suitable for making plastic electronic enclosures, medical containers, cosmetic containers, etc. We have all the production resources to make plastic blow molding machines with custom service.