Cold-Formed Steel Production Line

Request a Quote

Manufacturing Cold Formed Steel Sections

Cold-Formed Steel Production Line Model Selection

Cold-Formed Steel Production Line Model Selection

Our cold formed steel production mainly involves in steel uncoiling, flattening, roll forming and sizing. The thickness can be up to 22mm, coil weight up to 40MT, forming speed up to 80m/min, installed capacity up to 4500kw. While various types of cold formed steel products can be made by the cold forming steel production equipment: square tubes, steel piles and steel channels are three major products. Choose the machines for producing cold formed steel sections: uncoiler, levelling machine, shear end welder, roll forming machine, sizing mill, ect.

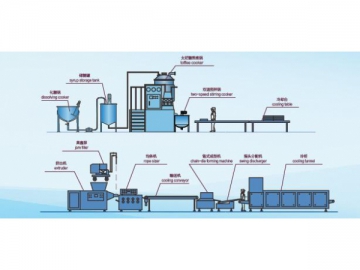

Cold-Formed Steel Production Process

Coil loading-Uncoiling-Flattening-Shearing, Butt welding-Roll forming-Welding-Water cooling-Sizing-Cut to length-Finished products collection

| Item | Model | Product spec.(mm) | Thickness (mm) | Coil weight (MT) | Forming speed (m/min) | Installed capacity ( kw ) | Floor area (m2) |

| 1 | 20× 20~50 × 50 | 1~3 | 5 | 20~80 | ~700 | 18× 100 | |

| 2 | 50× 50~100 × 100 | 2~8 | 5 | 20~80 | ~900 | 18× 100 | |

| 3 | 60× 60~150 × 150 | 2~10 | 10 | 20~60 | ~1700 | 21× 100 | |

| 4 | 80× 80~200 × 200 | 2.5~12.7 | 15 | 20~40 | ~1800 | 21× 130 | |

| 5 | 100× 100~250 × 250 | 3~14 | 20 | 15~30 | ~2800 | 21× 150 | |

| 6 | 120× 120~300 × 300 | 3~16 | 30 | 10~25 | ~3600 | 21× 160 | |

| 7 | 150× 150~350 × 350 | 4~18 | 30 | 8~20 | ~3800 | 24× 210 | |

| 8 | 200× 200~400 × 400 | 4~20 | 30 | 8~20 | ~4100 | 24× 240 | |

| 9 | 250× 250~500 × 500 | 4~22 | 40 | 8~20 | ~4500 | 24× 260 |

Related products

Send Message

Most Recent

More

Other Products

Videos