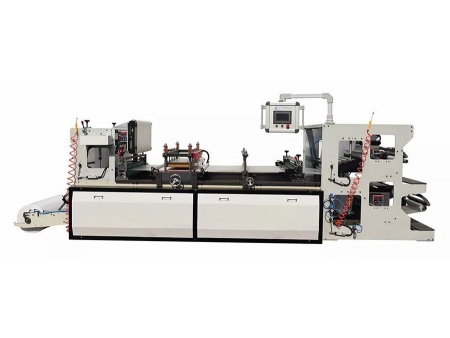

1500 Single Layer Air Bubble Film Making Machine

Our 1500 single layer air bubble filmmaking machine adopts once through forming craft and inner water cycle coolingmachine. Its design uses domestic and international advanced technologies.

Main Technical Parameter

| Model | DY-1500 |

| | Φ |

| Screw L/D ratio | 28:1 |

| Main and auxiliary extruder electrical power | 18.5KW |

| Width of finished product | |

| Main bubble specification | 10× |

| Output | 30 |

| Total installed capacity | 65kw |

| Overall dimension | |

| Gross weight | 5T |

1. Extruder

Structure

Frequencyconversion velocity modulation special-purpose velocity modulation motor

Speedreducer for the refined ZLYJ plastic rubber to squeeze out

38CRMOALalloy steel cylinder screw

Fastnet change organization

Stainlesssteel heating coil

Forcesthe air circulation blower

Specification

Drivingmotor: 18.5KW (frequency conversion velocity modulation)

Retarder: output torque 3500N.M

Cylinderscrew: Ф

Cylinderheat: heating capacity30KW

Fastfilter net change: lead screw nut promotion, lifting capacity 30KN

Temperaturecontrol: four zones auto-temperature control, max

Push output:

Features:

TheZLYJ branded special gear reducer for plastic extruder of our machine is madeup of high strength alloy steel and quality gear processed by carburizingquenching and grinding crafts. Thanks to the quality reducer of the extruder,our machine can run stable and own tiny size but high bearing capacity. Thecylinder screw of extruder is made of quality 38CrMoALA

2. T -mold

Structure

T flow channelspecially designed

Mold lip gap multi-spots regulation

The mold lip widthadjust in permission scope

Stainless steel heatingpipe built in

Specification

Mold lip gap: 0.3

Mold lip width: 500

Electric heating capacity: 30KW

3. Shape Part

Structure

A pair of

The manual clutchorganization

Shape roller tow motor

Shape roller motoroperated onset and retreat system

Specification

Bubble diameter:

Bubble height:

Bubble effective width:

Shape roller diameter:

Shape roller drivingmotor: 2KW

Shape roller maxmechanical speed:

Shape roller leveltraveling speed:

4. Tows Part

Structure

Tow roller with doubleroll to roll type

Tow driving motor

Cutter and itemizedevice

Specification

Roller diameter: Ф

Roller max mechanicalspeed:

Roller effective traction width:

Roller driving motor: 2KW

5. Rewinding Part

Structure

Double

Double axle manualclutch

auto-alarm with Fixed length

Specification

Rewinding width:

Rewinding diameter:

Rewinding torque motor:16N.M

6. Electronic Control

The electrical fission control system of ourmachine features the simple and convenient operation, Chinese and Englishlanguage interface, branded parts whichhave good quality and long service life. All these give our single layer airbubble film making machine more humanization andsimplification.

7. Spare Parts and Tools

| Standard configuration | ||

| Item | Description | quantity |

| 1 | Forming roller | 1pcs |

| 2 | Automatic Trimming device | 1pcs |

| 3 | Automatic Temperature Control | 12unit |

| 4 | Step less Inverter | 1set |

| 5 | Step Motor | 1set |

| 6 | AC Motor | 1set |

| 7 | Gear box | 1set |

| 8 | Panel box | 1set |

|

Related products

Send Message

Most Recent

More

Other Products

Videos

| ||